NSP-WFL bio-based wheel flange lubrication system

NSP-WFL is a highly effective and proven system for reducing friction and wear on railway components. It minimizes wear on wheel flanges and rails, saves fuel, and limits noise pollution.

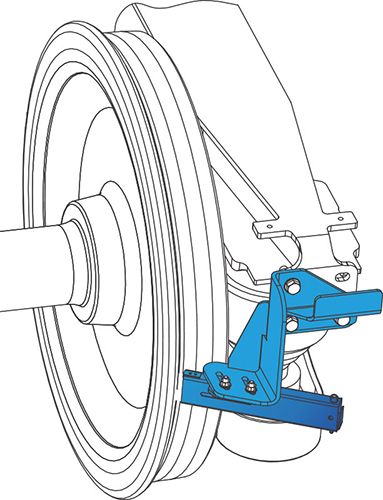

Our system is designed to lubricate the most vulnerable areas of wear, ensuring smoother wheel-rail cooperation. The solid sticks are pressed against the wheel flange using a spring mechanism, and the thin coating is passively transferred through the rail to subsequent wheels. This cost-effective and reliable method of wheel flange lubrication has been used successfully for many years on a range of railway systems, from freight and passenger locomotives to metro and commuter lines, and even heritage railways.

NSP-WFL is a cleaner, simpler, and less problematic alternative to on-board spray or trackside systems. It is also far more durable than any other solid lubricant, with our bio-based sticks lasting thousands of miles more than competitive lubricants. Our solid lubricant sticks are manufactured using a unique blend of soy and corn extracts mixed with graphite, ensuring excellent performance and environmental sustainability.

With NSP-WFL, you can achieve a higher level of transportation services while reducing maintenance costs, improving fuel efficiency, and increasing service availability. Trust in our proven system and let us help you improve the efficiency and sustainability of your railway operations.

Solid stick lubrication has been a trusted and reliable method for flange lubrication for decades. The system consists of three main elements: a solid lubricant stick, a spring-loaded applicator, and a holding bracket that positions the applicator towards the wheel. The simplicity and reliability of this solution make it the preferred choice of train operators.

NSP-WFL benefits:

- Extending wheel life by reducing flange wear

- Reducing rail wear

- Saving fuel and energy

- Limiting noise pollution

- More durable than competitive lubricants

- Environmentally friendly

- Compliant with EN16028 standards

- Low total operating cost

- Reduces the risk of derailments

With NSP-WFL, you can enjoy a reliable and efficient wheel flange lubrication system that improves the sustainability and performance of your railway operations. Contact us for more information on how we can help you achieve your goals.

Download

NSP-WFL brochure

language: Polish

file type: .pdf

NSP-WFL brochure

language: English

file type: .pdf